Dynamic Mechanical AnalysisNano-Clear® Property Overview

Dynamic Mechanical AnalysisNano-Clear® Property Overview

Conventional paint systems including epoxies provide good corrosion resistance and initial surface hardness, but unfortunately fall short in long-term UV resistance and weathering. Two-component polyurethanes provide good UV resistance and weathering, but typically cost much more than epoxy or polyester topcoats. Unfortunately conventional paint systems like topcoats and epoxies begin the oxidization process or “chalking” from weathering within 6 months from application. This surface chalking phenomenon is actually degraded paint that resides on the surface from UV exposure and weathering.

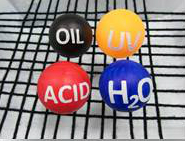

Nano-Clear® Coatings penetrate deep into the smallest pores within newly painted or highly oxidized paint surfaces to form a highly cross-link dense / hard coat surface. Nano-Clear® Coatings provide dramatically longer surface protection over conventional automotive, marine, aerospace and industrial paints including epoxies and polyurethanes. How can we make this claim? Nano-Clear® Coatings provide dramatically higher crosslink density over conventional one-component and two-component coating systems. Nano-Clear® Coatings prevent UV degradation of the substrate by absorbing harmful UV rays.

Crosslink density is defined as the concentration of chemical bonds within a polymer. Higher concentrations of chemical bonds within a polymer improve physical properties. Conversely, lower concentrations of chemical bonds within a polymer decrease physical properties. Increasing crosslink density increases material hardness, chemical resistance and long-term UV resistance.

What is crosslink density and why is it important in coatings?How does crosslink density relate to a coatings longevity?

High crosslink dense coatings provide increased molecular bonds. Increased molecular bonds are more difficult to break down by chemical attack, surface scratching and UV degradation from sunlight exposure. Highly crosslinked coatings provide increased physical performance and increased longevity over lower crosslinked coating systems.

How is Nano-Clear® Different?

Nano-Clear® Coatings are manufactured using proprietary 3D nanostructured polymers. These 3D nano-scale networks form the polymer backbone of all Nano-Clear® Coating Systems. Dynamic Mechanical Thermal Analysis (DMTA) is utilized to calculate the “crosslink density” of coating polymers. Nano-Clear® Coatings provide extreme crosslink density as measured using DMTA, including remarkable surface hardness, chemical resistance, extreme UV resistance and high flexibility. Interestingly enough, Nano-Clear® Coatings do not contain any nanoparticles like many marketed nanocoatings. Rather, all Nano-Clear® Coatings rely on crosslink density to exceed automotive OEM and aerospace OEM technical specifications.

– Nano-Clear® Coatings prevent the substrate from UV degradation by absorbing harmful UV rays.

– Nano-Clear® has 3X higher crosslink density over leading automotive OEM factory applied “high bake” clear coatings.