Nano-Clear® for Industrial Applications

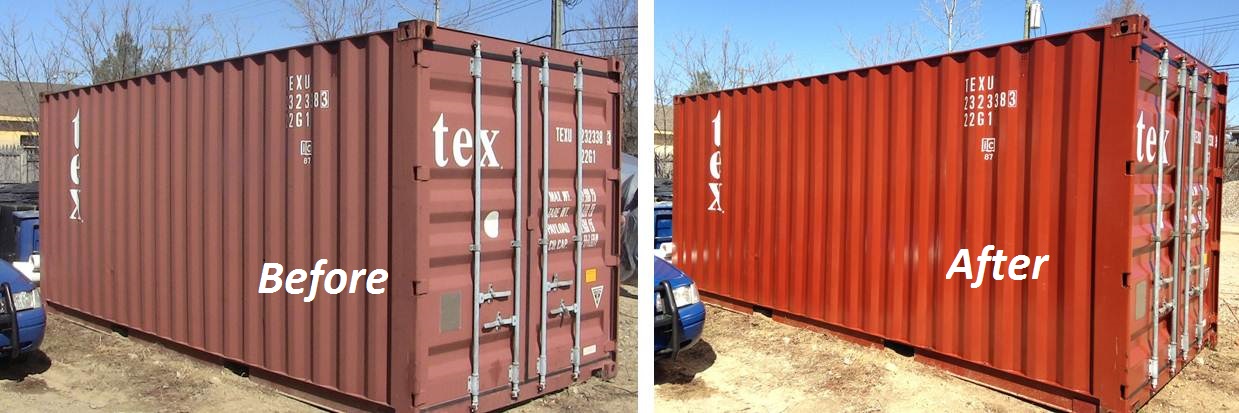

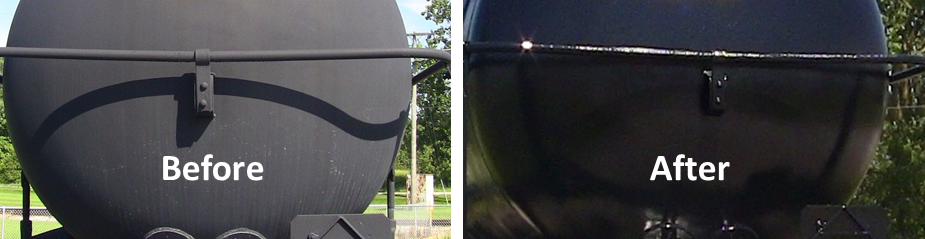

Weathered Paint + Nano-Clear® = 10 Year Performance Warranty

Global organizations have invested billions of dollars to protect valuable assets from corrosion, water damage, scratching, chipping, chemical attack and harmful UV rays. Many of these assets were painted using inferior materials not designed to withstand long-term weathering. Organizations have various options when these surfaces degrade from UV damage:

- Do nothing and allow the paint weathering cycle to continue (resulting in decreased corrosion, chemical and UV resistance).

- Replace the existing paint system using the same inferior conventional systems (epoxy topcoat, polyurethane or latex).

- Restore, enhance and extend the surface life of “New” or “Oxidized” painted assets by 10 years using Nano-Clear®.

Nano-Clear® NCI is the only industrial coating in the global marketplace to restore, enhance and extend the in-service life of highly oxidized surfaces by 10 years. Nano-Clear® provides extreme corrosion resistance, abrasion, chemical & UV resistance, water repellency and reduced surface maintenance. Nano-Clear® penetrates deep into the pores of newly painted or highly oxidized paints, enhances color, improves gloss, increases surface hardness and extends UV resistance. Nano-Clear® is a 1K humidity cured / highly cross-linked polyurethane hybrid nanocoating.

Nano-Clear® 1K physical properties are far superior to leading 2K industrial coatings including Imron® 2.1 HG

Nano-Clear® Industrial Coating Benefits:

– Extend Re-Paint Lifecycle by 2X

– Reduce Re-Paint Material Cost by 5X

– Reduce Re-Paint Labor Cost by 2X

– Reduce Surface Maintenance by 50%

Nano-Clear® Industrial Coatings have been validated and in-use by leading chemical tank car manufactures, Toshiba Industrial Products, Nippon Paint, Carnival Cruise Lines, Queen Elizabeth Cruise, Princimar Chemical Carriers, Odebrecht Oil & Gas…